OFFER

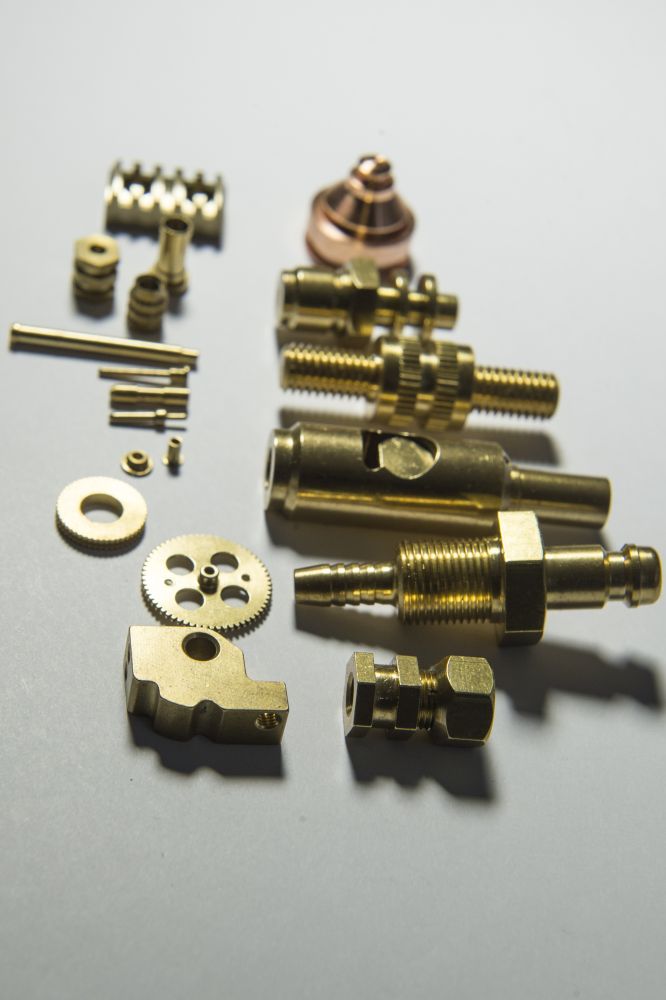

SARD specializes in the precision machining of

metal elements with small dimensions and complicated forms,

according to customers specific requirements.

⦁ CNC TURNING

• Details up to 150 mm in diameter and up to 400 mm in length on numerically controlled lathes,

• Details with a diameter of 0.1 to 42 mm on CNC machines and a turning length of 2-200 mm.

We have machines working in 2 to 8 axes.

⦁ CNC MILLING

- On 3, 4 and 5 - axis machining centres

- Processing of all conventional materials, i.e.: steel, brass, bronze, aluminium or stainless steel, as well as titanium and plastics

`⦁ CNC GRINDING, TROVALIZATION

Services in the field of:

- Turning on numerical machines - GILDEMEISTER, BOLEJ, MIYANO

- Turning on single-spindle lathes (from 0.3 to 40 mm)

- Turning on the six-spindle chucking and bar machines,

- Grinding holes, rollers and surfaces,

- Working on eccentric presses,

- Milling of cylindrical gears with a module from 0.2 to 8 mm on hobbing machines

- Chiselling of spur gears on the FELLOWSmortising machine up to 4 mm

- Planing of straight-toothed bevel gears on DLEASON planers up to a 2.5 mm module

- Thread rolling on rolling mills

- Parts produced to specific needs are made with heat treatment and galvanizing (galvanizing, chrome, gold, blacking)

WE ARE MOST PROUD OF:

- A diversified machine park with high production potential,

- A modern measurement laboratory equipped with optical and tactile coordinate measuring machines,

- Well trained staff.

All this enables medium and high-volume production, maintaining the highest quality, whilst maintaining the shortest delivery times and optimal prices.

We have built a solid reputation in machining since 1987.